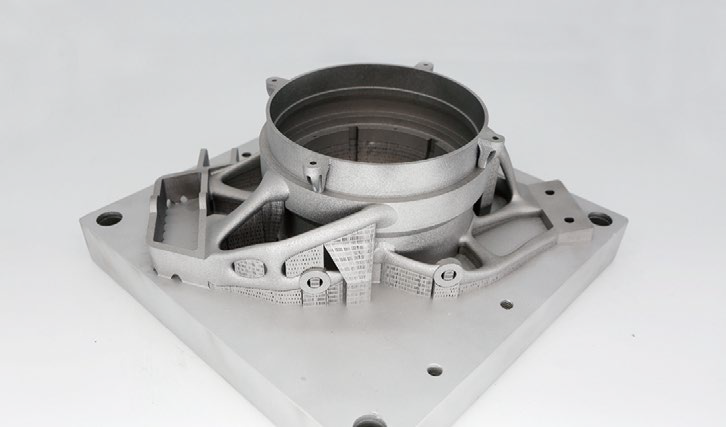

EP-M250 PRO Metal 3D Printer

The EP-M250 Pro is a dual-laser metal 3D printer that uses advanced metal powder bed fusion (MPBF) technology. It is capable of easily and quickly converting CAD data into high-performance,complex structure metal parts. The 3D printer is ideal for medium sized parts and small batch production.

Features

CONSISTENT PERFORMANCE

· Innovative gas flow management and optimized filter system ensures a stable building environment

· Outstanding sealing capability minimizes oxygen content

· Precise laser beam quality control

LOW OPERATION COST

· Quantitative powder feeding and coating ensure less powder waste

· Advanced filtration system signicantly increases lter lifetime

· Low inert gas consumption during purging and operation

HIGH PRODUCTIVITY

· Building volume of 262x262x350mm equipped with dual-laser system

· Non-stop operation during filter change

· Optimized recoating strategy shortens coating time

RELIABLE AND EASY OPERATION

· Convenient powder recycling systems and glove box structure minimize powder contact

· Intelligent software ensures less human intervention

· Real-time monitoring of the production environment and building process

Specification

Build Volume (X*Y*Z)

262x262x350mm

Optical System

Fiber Laser, 500W (single or dual-laser optional)

Spot Size

70um

Max Scan Speed

8m/s

Layer Thickness

20-100um

Materials

Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc.

Power Supply

380V, 20A, 50/60Hz, 14KW

Gas Supply

Ar/N₂

Oxygen Content

≤100ppm

Dimension (W*D*H)

3500x1300x2300mm

Weight

1700kg

Software

EP Control, EP Hatch

Input Data Format

STL or Other Convertible File

Please contact us before order it.