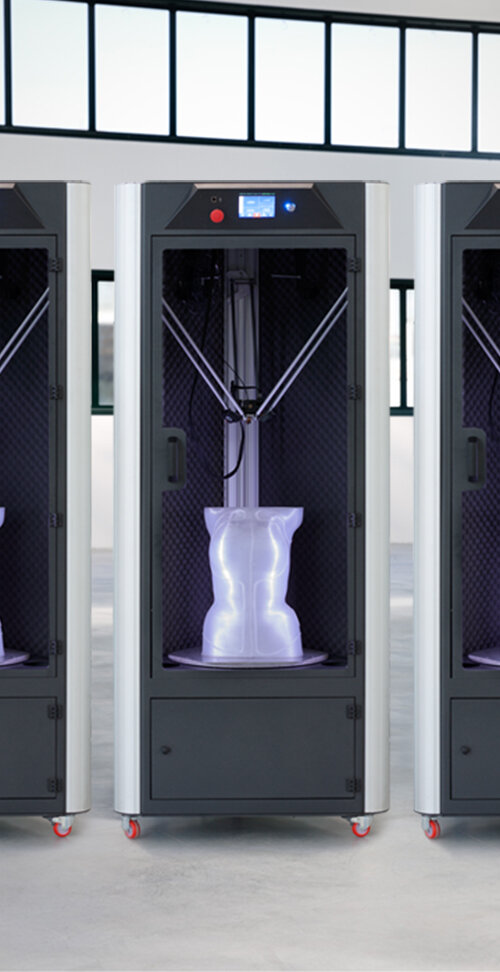

Delta WASP 4070 INDUSTRIAL X

Delta WASP 4070 INDUSTRIAL X

Please contact us before you order it.

Manufacture parts quickly using the strongest technical materials with professional 3D printer Delta WASP 4070 INDUSTRIAL X. Thanks to the new system featuring a heated chamber and cooled mechanics, printing technical materials it’s even easier.

Industrial tools

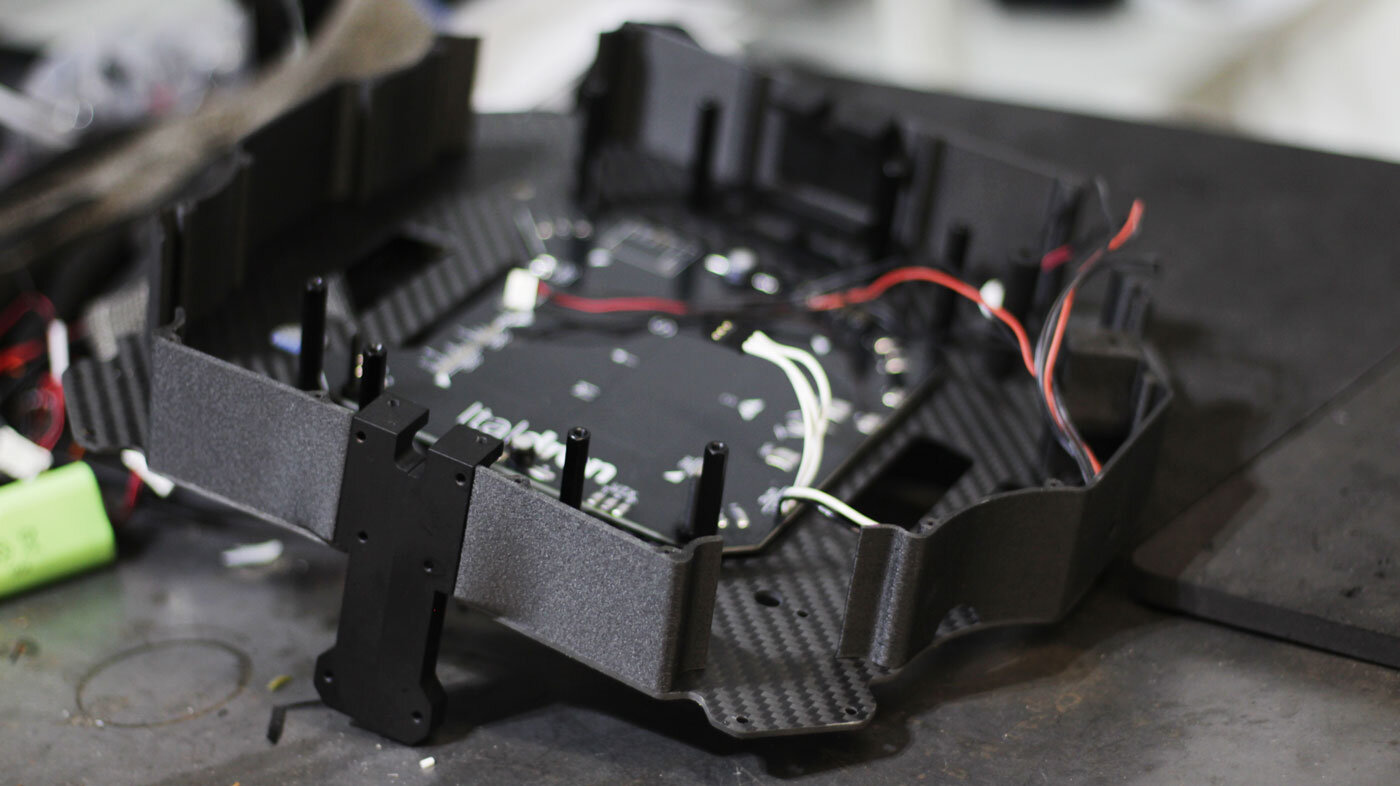

Dual extruder WASP ZEN X Extruder for single and multi-material prints. Different materials from 0 to 350 ° with the same cartridge and with the possibility to easily switch nozzles with multiple diameters.

Swapping the WASP ZEN X Extruder for the WASP FLEX Extruder to print soft materials (up to shore 50A) takes only few minutes.

The external Bowden replaces the suspended thanks to the new “Filament driver X”. The grip on the filament is doubled and the force tripled thanks to two hardened steel gears and a gearbox.

Industrial 3d printer

Delta WASP 4070 INDUSTRIAL X is manufactured in metal with strong steel core belts and features a thermal and acoustic insulation.

“Hot and Cold technology” allows the control of room temperature up to 70°C and cools down the mechanics making the print of technical materials easier.

Delta WASP 4070 INDUSTRIAL X can be connected to Wifi network so that you can manage your printer from smartphone, tablet or PC.

Inside the printer there’s now a camera for monitoring the print even from afar.

WASP PLUS +

HIGH RESOLUTION

100 Micron

HUGE VOLUMES

Ø 400 mm x 700 mm = 28 l

HIGH SPEED

Printing speed: 200 mm/s

Maximum travel speed: 300 mm/s

Acceleration: 6.000 mm/s2

HEATED CHAMBER

Max Temp 70°

WIFI REMOTE

WIFI: machine connected to the network for monitoring and control

New GUI: new touch interface with bigger TFT display

Camera on-board: for monitoring and timelapse

Remote intervention: WASP technicians can work from remote on your board in case of issues

MULTIPLE MATERIALS

ASA - ABS - HIGH-IMPACT PS - PETG - TPU - TPE - POLYPROPYLENE - POLYCARBONATE - PC+ABS - PPS - PMMA - PVA - PA - PA carbon - PLA

FIRMWARE UPDATE

Continuous Print: when the used extruder runs out of filament,

the print continues with the other extruder

Bed safety sensor: automatic security system

Gcode analyzer: gcode error checking system

Auto check: automatic error recognition routine

Mesh auto calibration: mesh plate calibration

HOT AND COLD TECHNOLOGY (cc)

An efficient way of heating by two internal heat sources, makes possible to ensure work temperatures up to 80 °C, without burdening the mechanical parts of the machine.

RESURRECTION SYSTEM (cc)

A system which allow users to save their print job and resume it in the case of power failure.

FREE ZETA SYSTEM (cc)

It allows to print a file starting from a precise height of the model to be printed, height previously selected.